| Availability: | |

|---|---|

| Quantity: | |

SQ-2220E Industrial Rubber Roll Dye Sublimation Printer With I3200 Heads

SQ-2220E Industrial Rubber Roll Dye Sublimation Printer With I3200 Heads

| Technical Specifications | ||

| MODEL | SQ-2220E | |

| PRINT HEAD | TYPE | Epson13200-A1 |

| HEAD NUMBER | 20 | |

| INK DOT SIZE | 3.5pl | |

| PRINTING SPEED | 1 PASS | 900㎡/h |

| 2 PASS | 450㎡/h | |

| INK CARTRIDGES | TYPE | Ultra-high/high concentration dye sublimation ink |

| COLOR | 4colors(C/M/Y/K) 6colors(C/M/Y/K/Lc/Lm) | |

| SUPPLY METHOD | Negative pressure ink supply | |

| CAPACITY | 20L ink tank | |

| PRINTER WIDTH | 2250mm | |

| PRINTING WIDTH | 2050mm | |

| X-AXIS DRIVE | Linear motors | |

| ENCODER STRIP | Metal encoder strip | |

| STRUCTURE | Heavy-duty industrial structure | |

| LOADING AND TAKE-UP STRUCTURE | Rear retraction / 10,000 meters high-performance servo motor system | |

| MAXIMUM MEDIA LOAD | ≤10000m | |

| MINIMUM MEDIA WEIGHT | 30 | |

| DRYING STRUCTURE | External three-stage automatic control air and heat integrated dryer | |

| MOISTURIZING STRUCTURE | Fully automatic cleaning and moisturizing integrated components | |

| RIP | Riprint / Neostampa / Wasatch / Photoprint | |

| IMAGE FORMAT | JPG,TIF,PDF,etc. | |

| PC CONFIGURATION | OPERATING SYSTEM | Win7 64-bit/Win10 64-bit |

| HARDWARE REQUIREMENTS | Hard disk: 500G or more (SSD recommended); Running memory above 8G; Graphics card: ATI dedicated 4G memory; CPU: i7 processor | |

| INTERFACE | USB3.0 | |

| POWER REQUIREMENTS | POWER SUPPLY | AC220V±5%,16A,50Hz |

| PRINTING SYSTEM | 5000W | |

| DRYING SYSTEM | MAX :18KW | |

| STANDARD COMPONENTS | PLC automatic control system / humanized operation interface / automatic ink supply detection system /external automatic control air heat integrated drying, etc | |

| ENVIRONMENT | TEMPRETURE:15℃-32℃ HUMIDITY:30%-75%(no condensation) | |

| PRINTER DIMENSION | 4050x2491x2070mm | |

| WIGHT(WITH STAND) | 1.75T | |

| Technical Specifications | ||

| MODEL | SQ-2220E | |

| PRINT HEAD | TYPE | Epson13200-A1 |

| HEAD NUMBER | 20 | |

| INK DOT SIZE | 3.5pl | |

| PRINTING SPEED | 1 PASS | 900㎡/h |

| 2 PASS | 450㎡/h | |

| INK CARTRIDGES | TYPE | Ultra-high/high concentration dye sublimation ink |

| COLOR | 4colors(C/M/Y/K) 6colors(C/M/Y/K/Lc/Lm) | |

| SUPPLY METHOD | Negative pressure ink supply | |

| CAPACITY | 20L ink tank | |

| PRINTER WIDTH | 2250mm | |

| PRINTING WIDTH | 2050mm | |

| X-AXIS DRIVE | Linear motors | |

| ENCODER STRIP | Metal encoder strip | |

| STRUCTURE | Heavy-duty industrial structure | |

| LOADING AND TAKE-UP STRUCTURE | Rear retraction / 10,000 meters high-performance servo motor system | |

| MAXIMUM MEDIA LOAD | ≤10000m | |

| MINIMUM MEDIA WEIGHT | 30 | |

| DRYING STRUCTURE | External three-stage automatic control air and heat integrated dryer | |

| MOISTURIZING STRUCTURE | Fully automatic cleaning and moisturizing integrated components | |

| RIP | Riprint / Neostampa / Wasatch / Photoprint | |

| IMAGE FORMAT | JPG,TIF,PDF,etc. | |

| PC CONFIGURATION | OPERATING SYSTEM | Win7 64-bit/Win10 64-bit |

| HARDWARE REQUIREMENTS | Hard disk: 500G or more (SSD recommended); Running memory above 8G; Graphics card: ATI dedicated 4G memory; CPU: i7 processor | |

| INTERFACE | USB3.0 | |

| POWER REQUIREMENTS | POWER SUPPLY | AC220V±5%,16A,50Hz |

| PRINTING SYSTEM | 5000W | |

| DRYING SYSTEM | MAX :18KW | |

| STANDARD COMPONENTS | PLC automatic control system / humanized operation interface / automatic ink supply detection system /external automatic control air heat integrated drying, etc | |

| ENVIRONMENT | TEMPRETURE:15℃-32℃ HUMIDITY:30%-75%(no condensation) | |

| PRINTER DIMENSION | 4050x2491x2070mm | |

| WIGHT(WITH STAND) | 1.75T | |

Widely used in: fashion clothing, home textile fabrics, swimwear, T-shirts, canvas bags, cushions, flags, textile fabrics, etc.

Using advanced board control technology, equipped with 20 i3200-A1 print heads.3.5pl ink drops. lndustrial grade design ensures the printhead is durable. New automatedproduction program, high-strength industrial design structure, can be equipped with10,000 meters of whole roll of base paper carrying performance, fully realize unattended automated production program, making productivity further improved.

Back putting and receiving device, equipped with 10,000 meters of whole roll of base paper carrying performance;

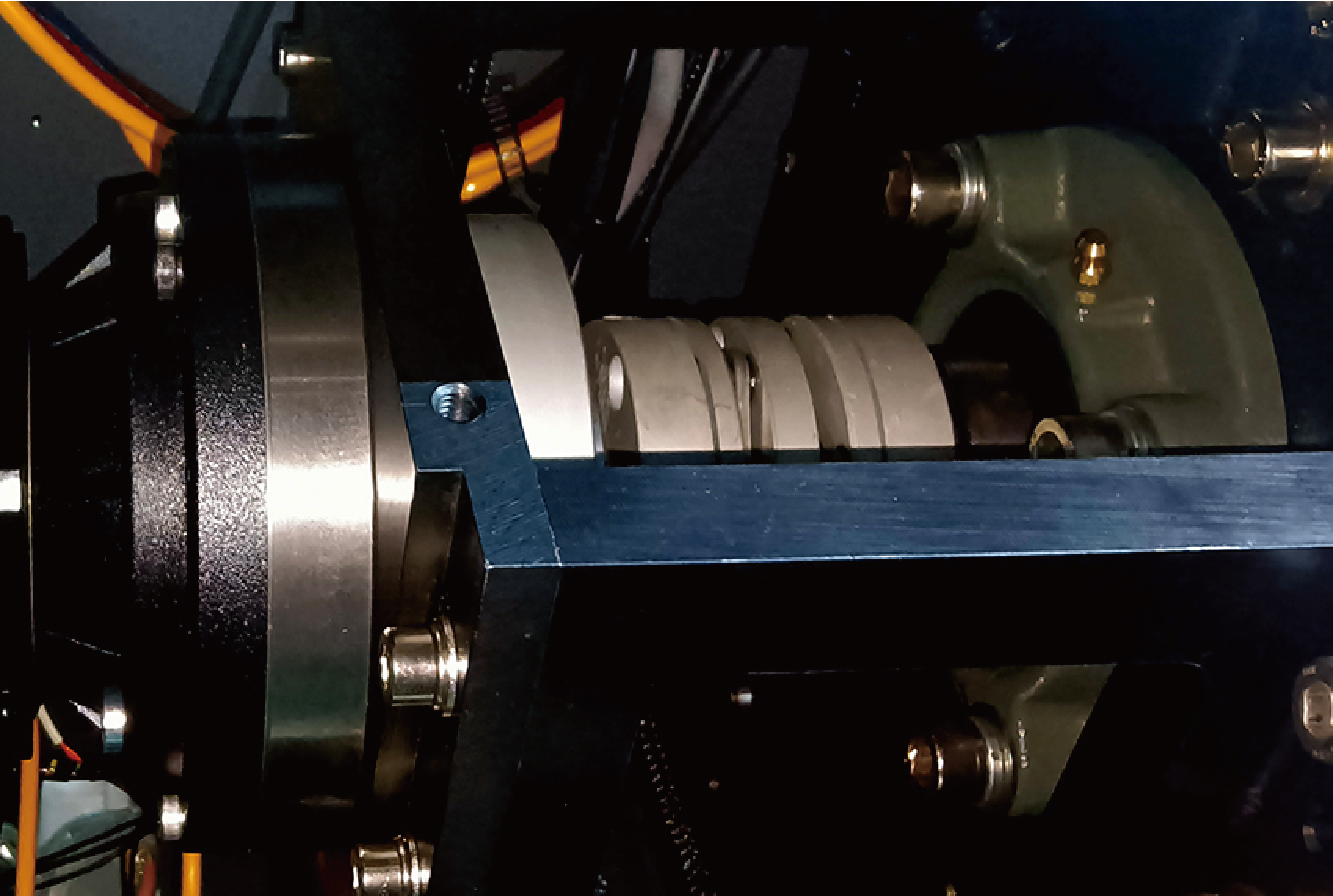

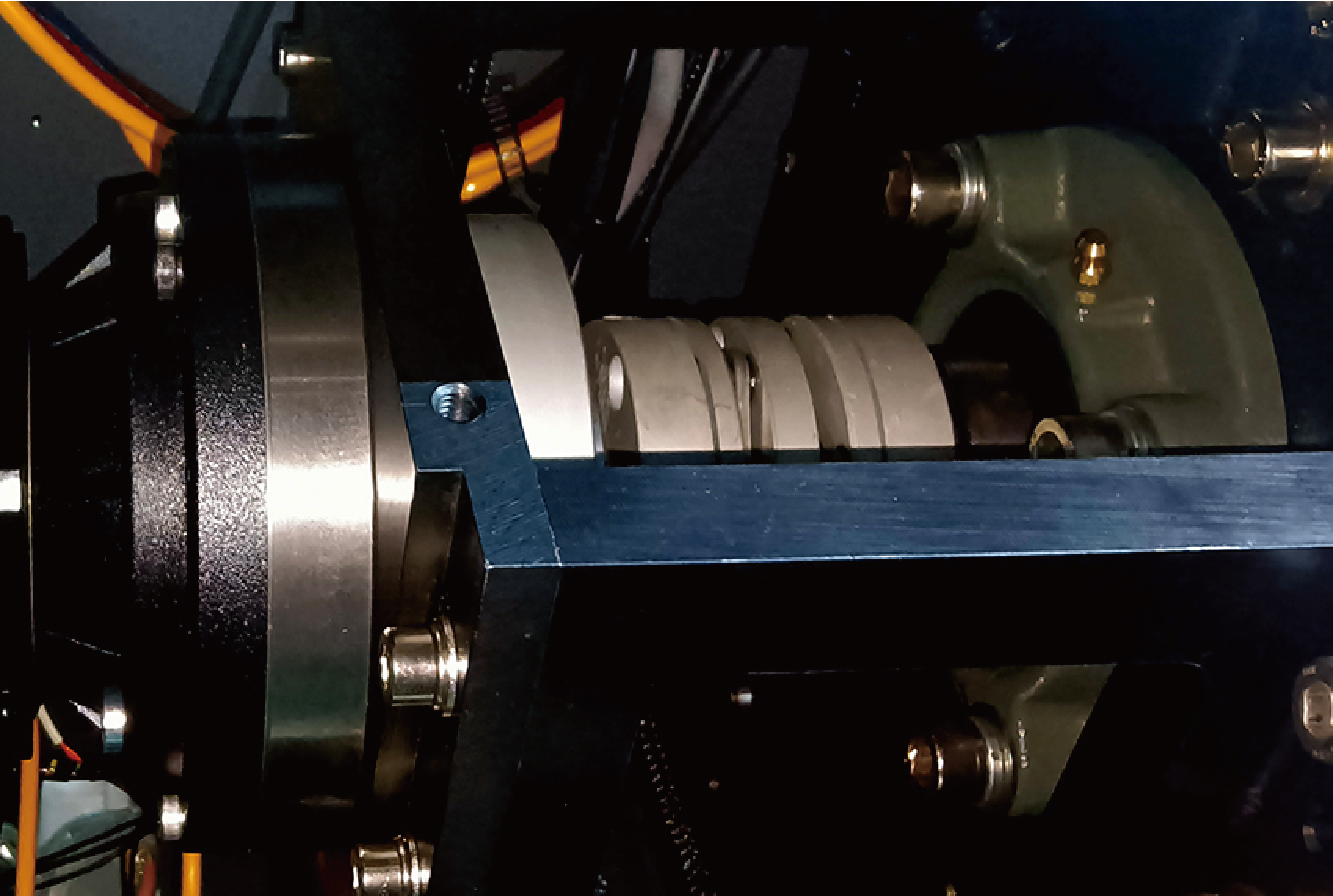

High stability imported metal grating is more durable, and improve the stability of printing to ensure high-quality continuous output;

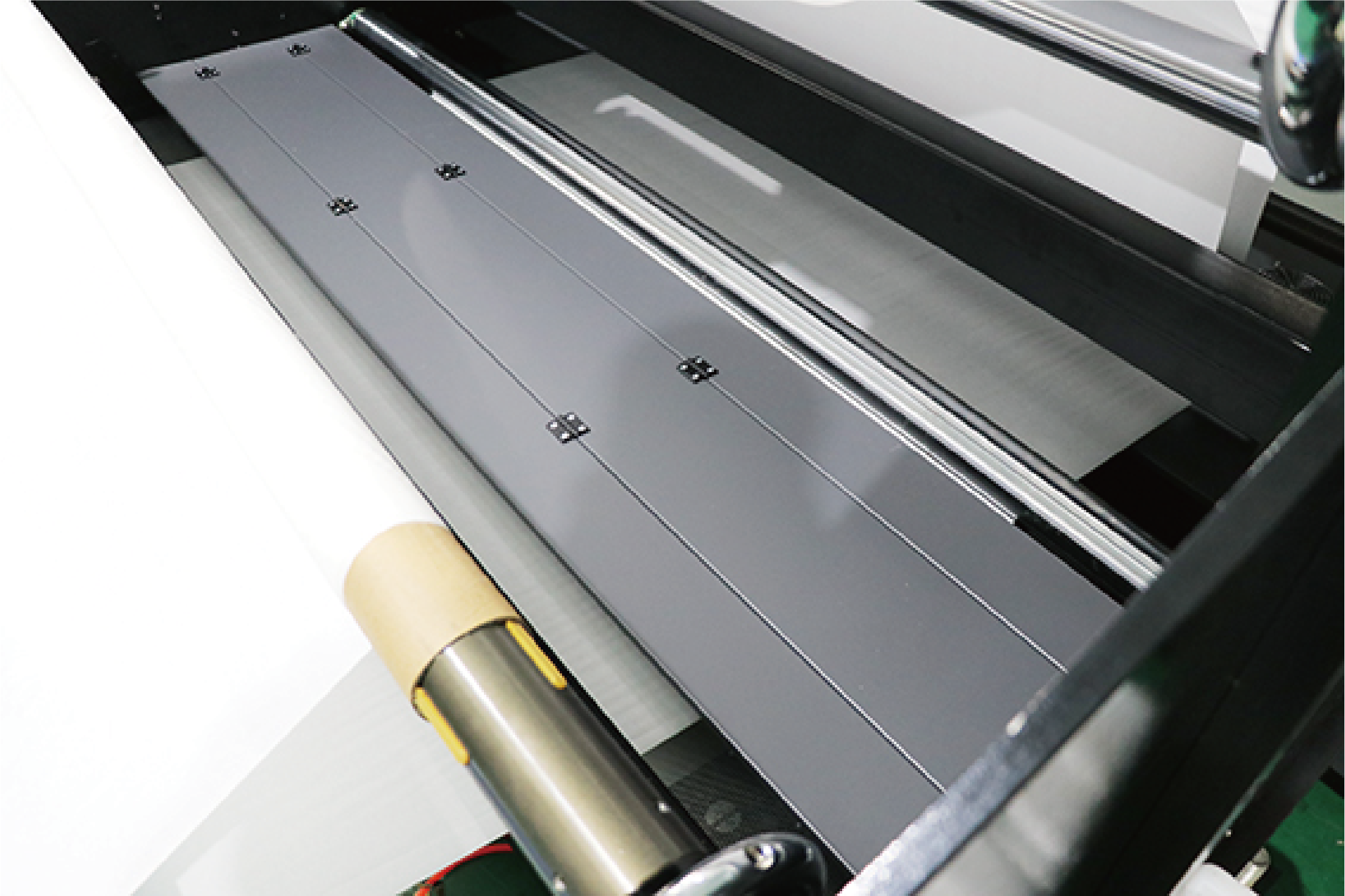

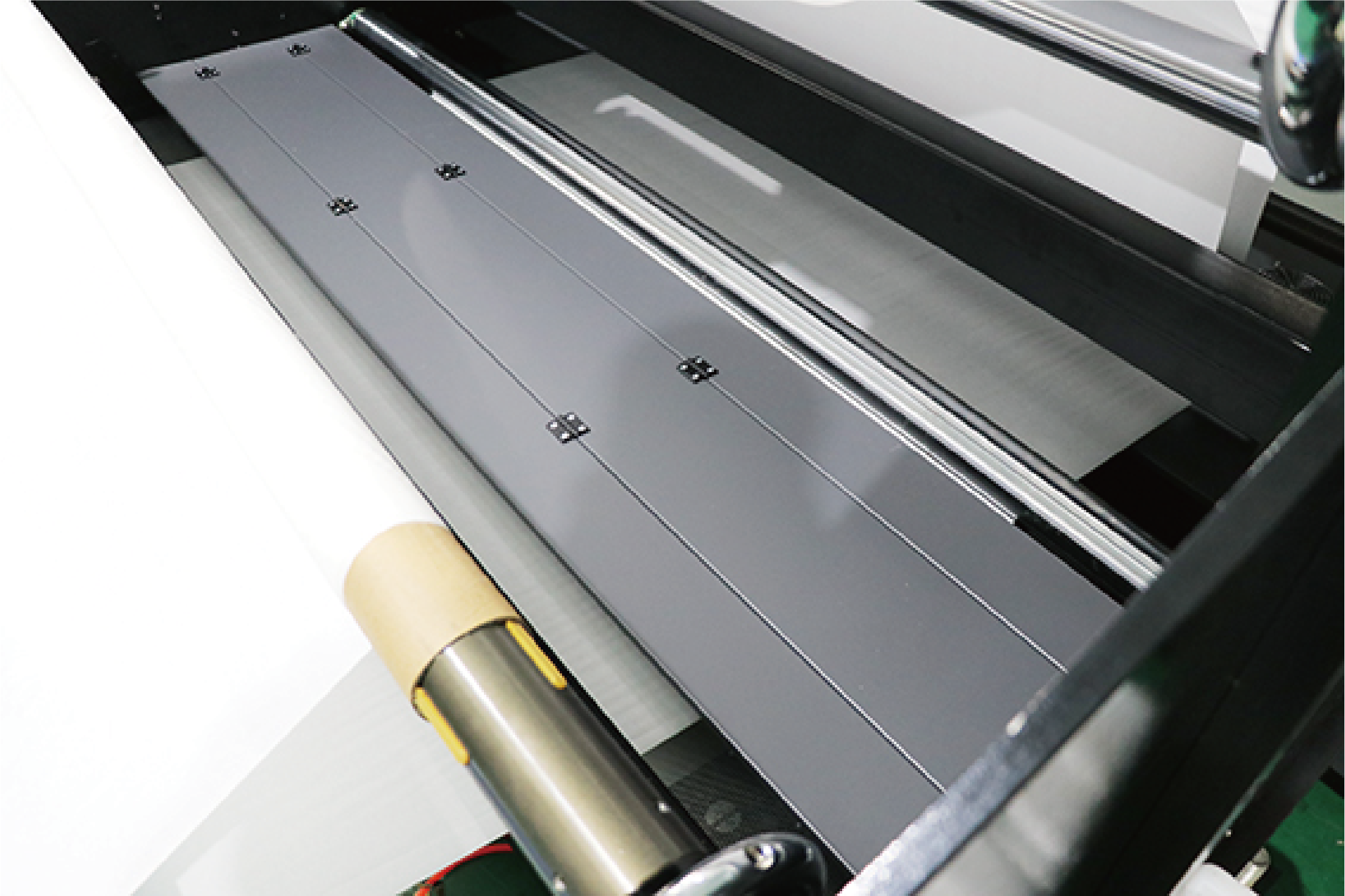

lntegrated platform, smooth material, paper is not easy to drum, improve the output quality, platform calibration and adjustment more convenient;

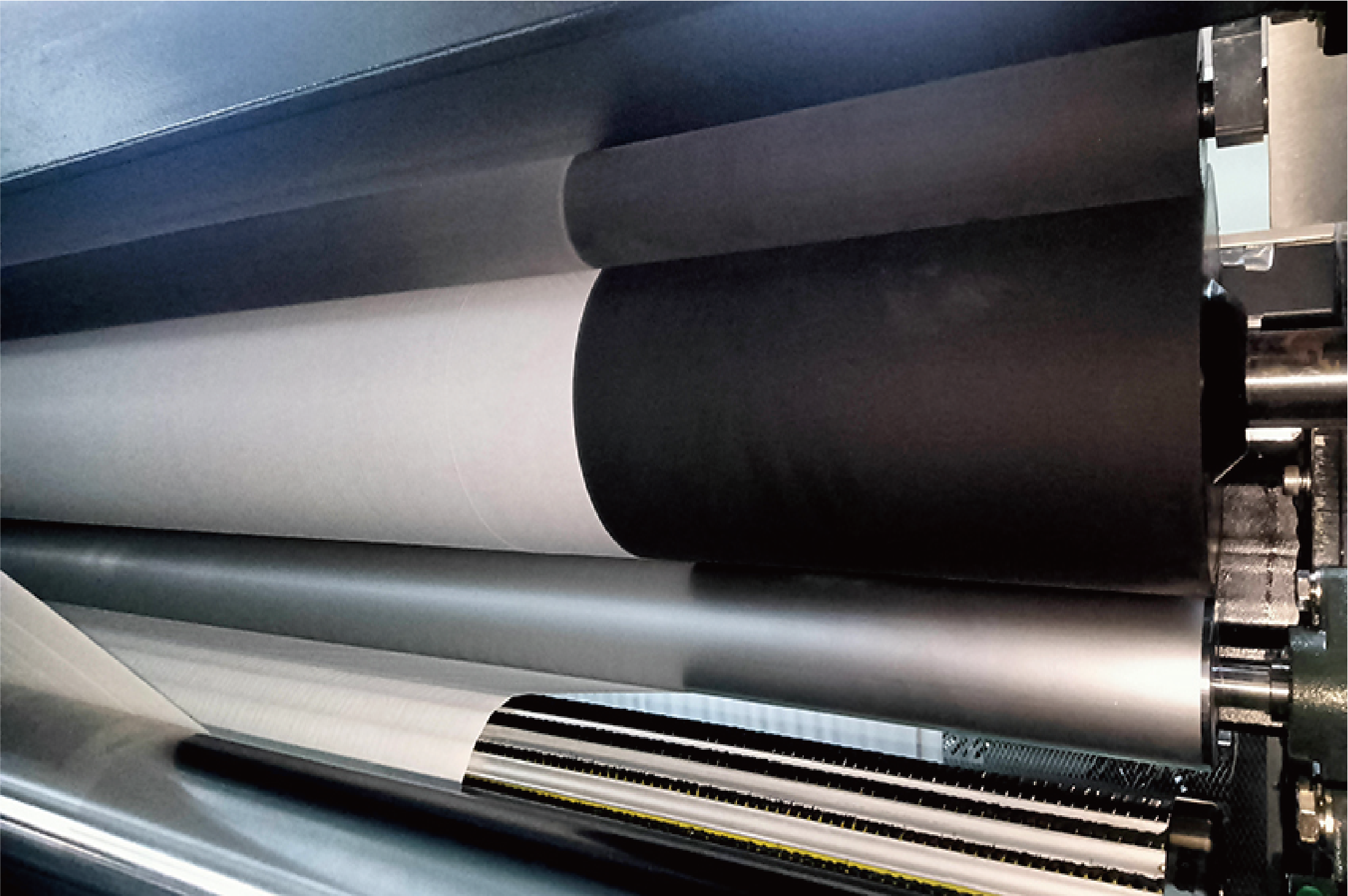

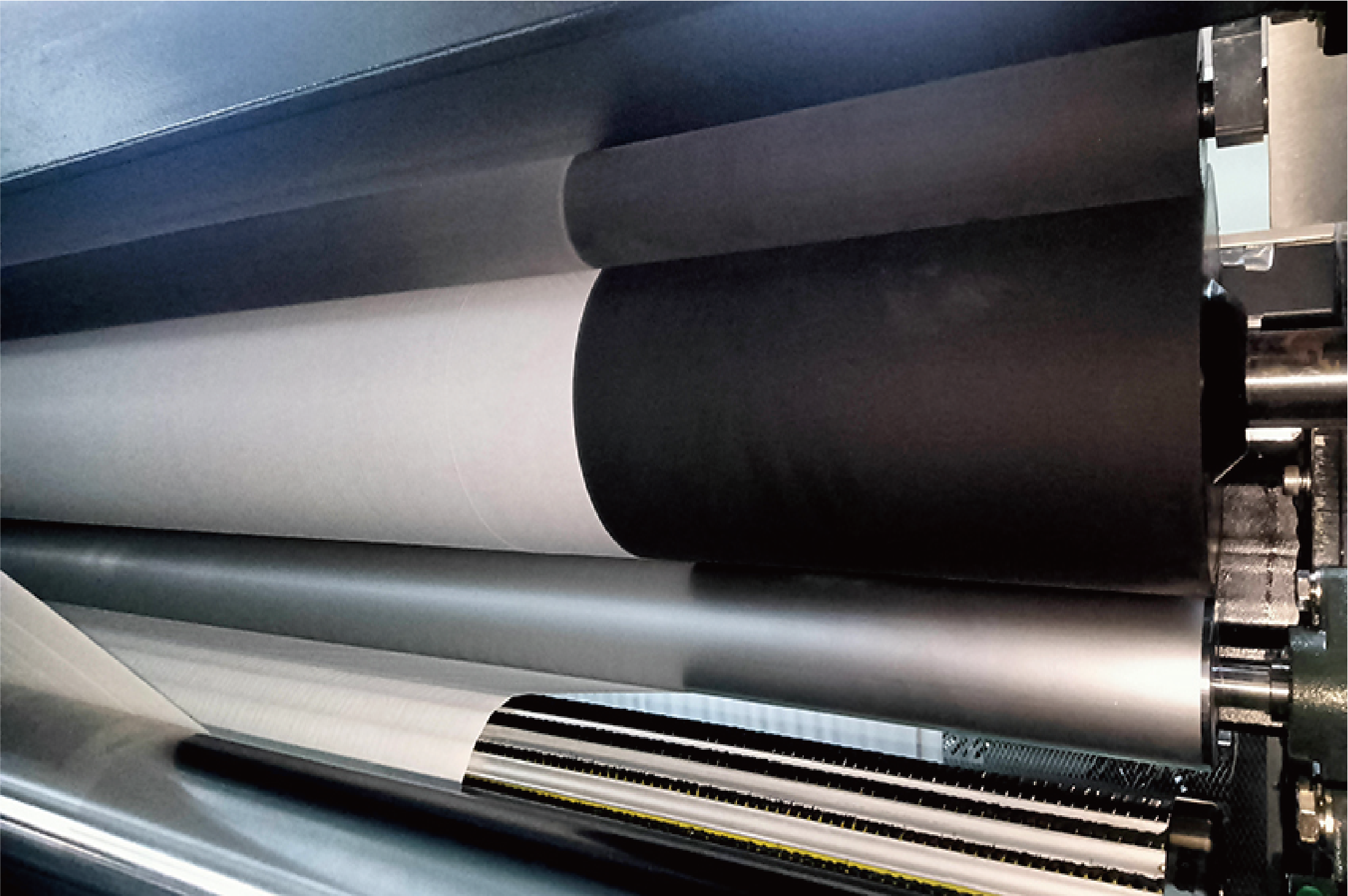

The rubber roller make paper more uniform, hich-precision output, and not easy to press wheel printing andpaper wrinkling;

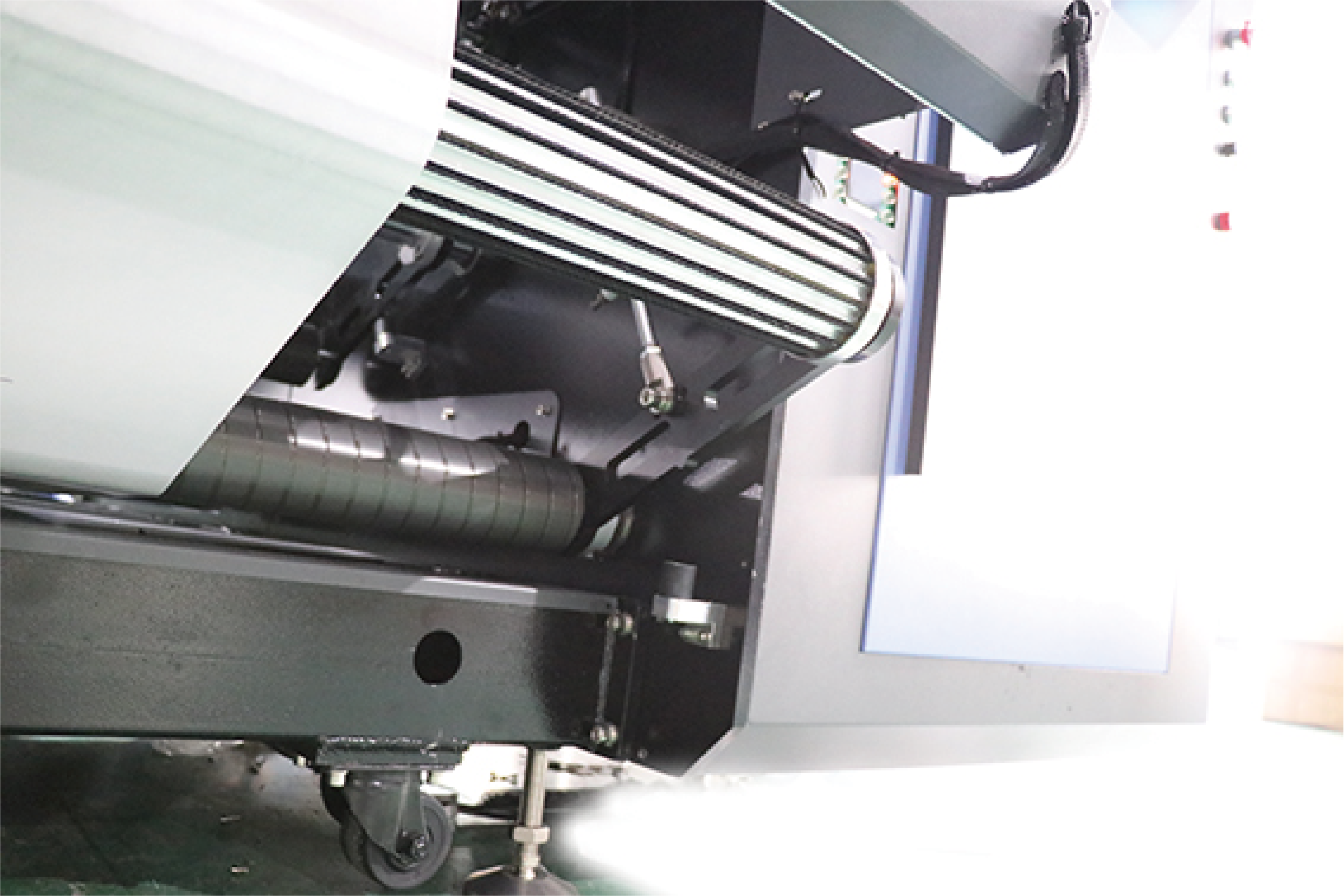

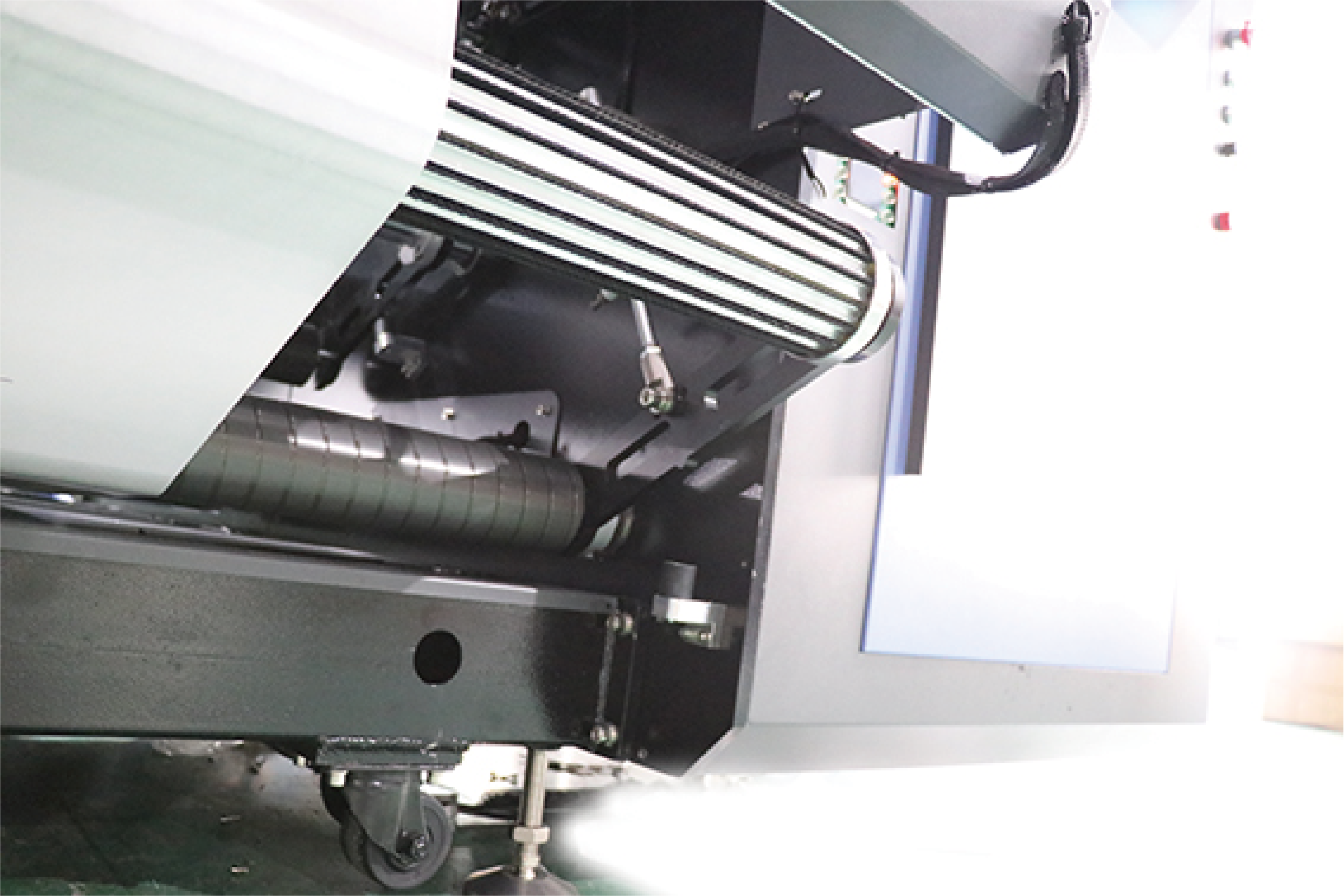

The front bottom and the back of the three sections are dried in one body, which is more convenient forloading and unloading materials, improve drying efficiency, and more suitable for customer proofing;

Effectively solve the step deviation and speed difference caused by the diameter of different materials.to ensure that the receiving material is neat;

Can better meet the needs of mass production, save loading and unloading time, improve production efficiency;

The spiral paper feed poel ensures smooth steppingof various paper by reducing media folds during loadingand increasing the friction of the active shaf.

Thickened and highly stable imported metal encoder.high-density linear motor, more durable, improves thestability of printing, greatlyand ensures high-qualitycontinuous output.

Integrated platform, stable feeding, paper is not easy to bulgeimprove output quality, platform calibration and adjustment ismore convenient.

Industrial rubber roller feeds ensure the paper more uniformlyhigh-precision output, and is not easy to appear pressurewheel printing and paper wrinkling during the printing.

Adjustable speed motor, compared with the traditional motorspeed increased by 70%,paper feed is more stable.

PLC automatic control system, operation interfaceto provide more convenient and comprehensive services.

Integrated drying at the bottom is more convenient for loadingand unloading materials, improving drying efficiencyand more suitable for customer proofing.

High-performance servo motor , 10000 meters winding effectivelysolves the step deviation and speed deterioration causedby different material diameters and sizes, and ensures thatthe receiving materials are neat.

Configuration tension system makes the printing process more stableprinting efficiency.

Widely used in: fashion clothing, home textile fabrics, swimwear, T-shirts, canvas bags, cushions, flags, textile fabrics, etc.

Using advanced board control technology, equipped with 20 i3200-A1 print heads.3.5pl ink drops. lndustrial grade design ensures the printhead is durable. New automatedproduction program, high-strength industrial design structure, can be equipped with10,000 meters of whole roll of base paper carrying performance, fully realize unattended automated production program, making productivity further improved.

Back putting and receiving device, equipped with 10,000 meters of whole roll of base paper carrying performance;

High stability imported metal grating is more durable, and improve the stability of printing to ensure high-quality continuous output;

lntegrated platform, smooth material, paper is not easy to drum, improve the output quality, platform calibration and adjustment more convenient;

The rubber roller make paper more uniform, hich-precision output, and not easy to press wheel printing andpaper wrinkling;

The front bottom and the back of the three sections are dried in one body, which is more convenient forloading and unloading materials, improve drying efficiency, and more suitable for customer proofing;

Effectively solve the step deviation and speed difference caused by the diameter of different materials.to ensure that the receiving material is neat;

Can better meet the needs of mass production, save loading and unloading time, improve production efficiency;

The spiral paper feed poel ensures smooth steppingof various paper by reducing media folds during loadingand increasing the friction of the active shaf.

Thickened and highly stable imported metal encoder.high-density linear motor, more durable, improves thestability of printing, greatlyand ensures high-qualitycontinuous output.

Integrated platform, stable feeding, paper is not easy to bulgeimprove output quality, platform calibration and adjustment ismore convenient.

Industrial rubber roller feeds ensure the paper more uniformlyhigh-precision output, and is not easy to appear pressurewheel printing and paper wrinkling during the printing.

Adjustable speed motor, compared with the traditional motorspeed increased by 70%,paper feed is more stable.

PLC automatic control system, operation interfaceto provide more convenient and comprehensive services.

Integrated drying at the bottom is more convenient for loadingand unloading materials, improving drying efficiencyand more suitable for customer proofing.

High-performance servo motor , 10000 meters winding effectivelysolves the step deviation and speed deterioration causedby different material diameters and sizes, and ensures thatthe receiving materials are neat.

Configuration tension system makes the printing process more stableprinting efficiency.

Catalog download address:

SQ-2220E Industrial Rubber Roll Dye Sublimation Printer With I3200 Heads

Catalog download address:

SQ-2220E Industrial Rubber Roll Dye Sublimation Printer With I3200 Heads

GREEN FUTURE . GREEN GREEN