| Availability: | |

|---|---|

| Quantity: | |

SQ-1816EP Digital Textile Pigment Printing Machine With I3200 Heads

SQ-1816EP Digital Textile Pigment Printing Machine With I3200 Heads

| Technical Specifications | |

| MODEL | SQ-1816EP |

| NAME | Digital Textile Pigment Printing Machine |

| PRINT HEAD | Epson13200-A1 |

| HEAD NUMBER | 16 |

| MAXIMUM PRINT WIDTH (mm) | 1800 |

| MAXIMUM DIAMETER RANGE (mm) | 300 |

| MAXIMUM WEIGHT RANGE(Kg) | 100 |

| PRINTING SPEED ( ㎡/h) (paint) | CMYK:720X1200-4pass:160sqm/h |

| CMYKRGBOr:720X1200-4pass:90sqm/h | |

| INK TYPE | Paint, dispersion, high tempreture dispersion |

| INK COLOR | CMYK/C、M、Y、K、R、G、B、Or |

| PRINTING MEDIUM | Cotton |

| SUPPORT FOR IMAGE TYPES | JPG/TIFF/BMP/Other |

| RIP SOFTWARE | NeoStampa |

| MACHINE SIZE | 3680*2200*1720 |

| POWER(Kw) | Printer: 8Kw; Dryer: 20Kw |

| WORKING TEMPRETURE | 20-30℃ |

| WORKING HUMIDITY | 45%-70%(no condensation) |

| DRYER OPTION | Electric heating |

| Technical Specifications | |

| MODEL | SQ-1816EP |

| NAME | Digital Textile Pigment Printing Machine |

| PRINT HEAD | Epson13200-A1 |

| HEAD NUMBER | 16 |

| MAXIMUM PRINT WIDTH (mm) | 1800 |

| MAXIMUM DIAMETER RANGE (mm) | 300 |

| MAXIMUM WEIGHT RANGE(Kg) | 100 |

| PRINTING SPEED ( ㎡/h) (paint) | CMYK:720X1200-4pass:160sqm/h |

| CMYKRGBOr:720X1200-4pass:90sqm/h | |

| INK TYPE | Paint, dispersion, high tempreture dispersion |

| INK COLOR | CMYK/C、M、Y、K、R、G、B、Or |

| PRINTING MEDIUM | Cotton |

| SUPPORT FOR IMAGE TYPES | JPG/TIFF/BMP/Other |

| RIP SOFTWARE | NeoStampa |

| MACHINE SIZE | 3680*2200*1720 |

| POWER(Kw) | Printer: 8Kw; Dryer: 20Kw |

| WORKING TEMPRETURE | 20-30℃ |

| WORKING HUMIDITY | 45%-70%(no condensation) |

| DRYER OPTION | Electric heating |

|

Cost-effective industrial rack, industrial production capacity

High eficiency, low cost, high precision to create excellent printing quality, ultra-high cost to meet the fast one-

click printing and high-end design customization needs.

|

HD printing, imaging details are clear.

High speed and stability, one key design customization Using linear motor + magnetic grid + magnetic levitation,greatly improve the stability of printing to ensure high-quality continuous output, through special combination andcontrol svstem to maximize the productivity of the nozzle. so that vou can face mass orders can also be handy.

|

Intelligent design, easy to understand operation

Automatic print head cleaning system, moisturizing system, automatic belt cleaning and maintenance system design.simple operation and maintenance, protect the eficiency of the machine, make it possible for one person tooperate the machine.

|

Detail creation, perfect printing experience

The operation is simple. the coth surface fattening effect is good. modular desian, the maintenance of each componentis convenient and brief, the ink replacement is quick and convenient, the degree of automation is high, the print head iscleaned by one key and moisturized by one key.

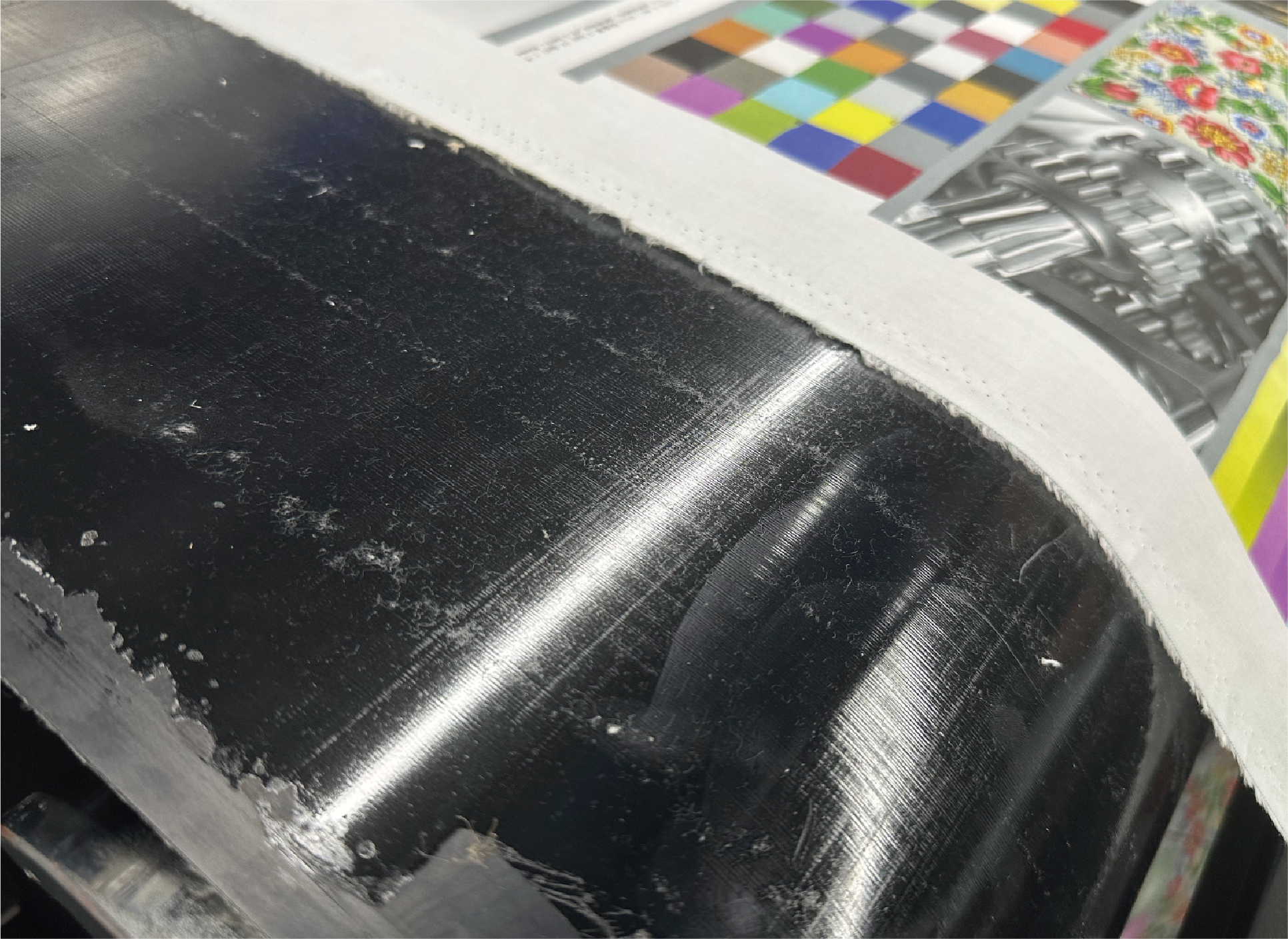

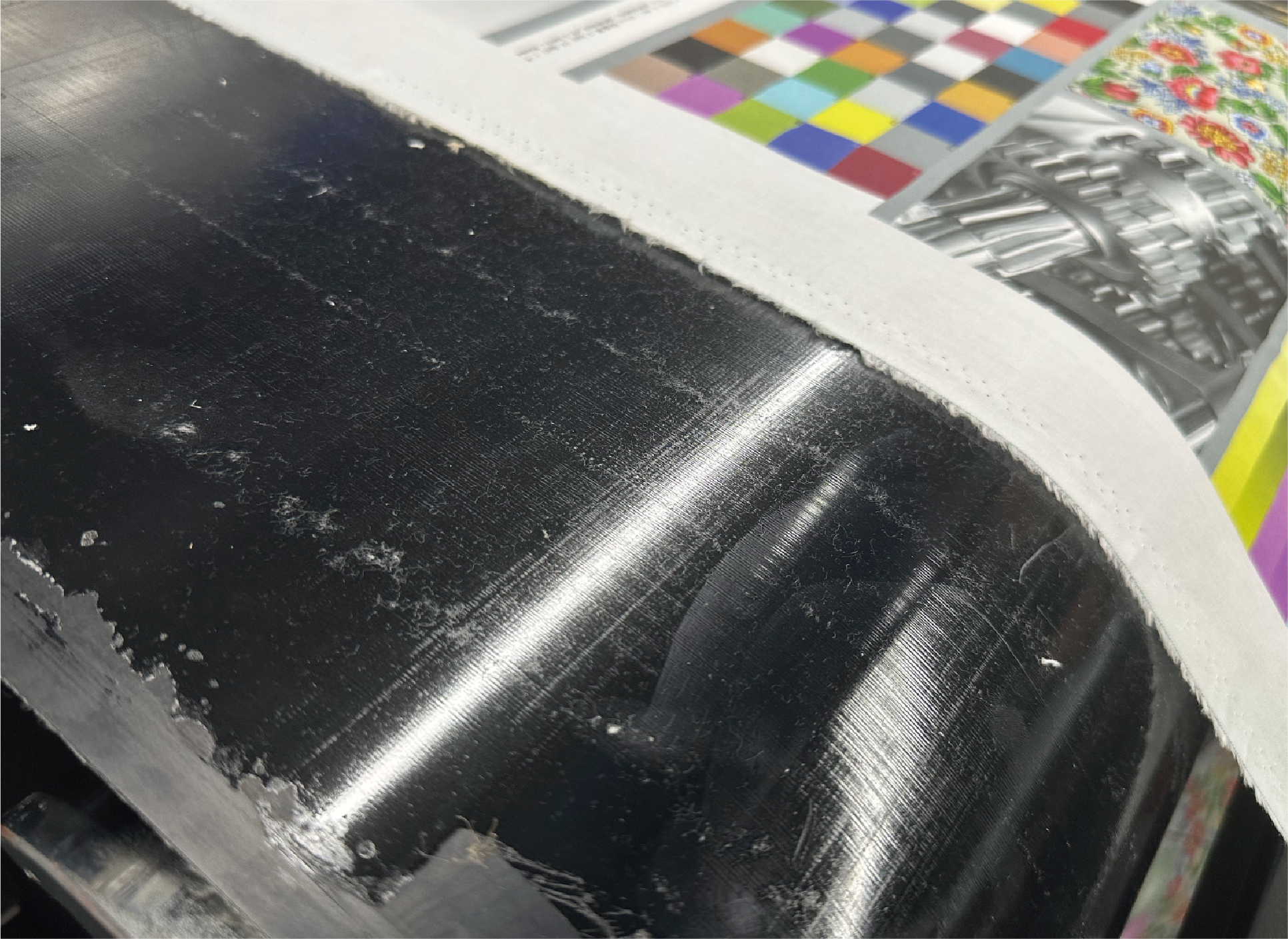

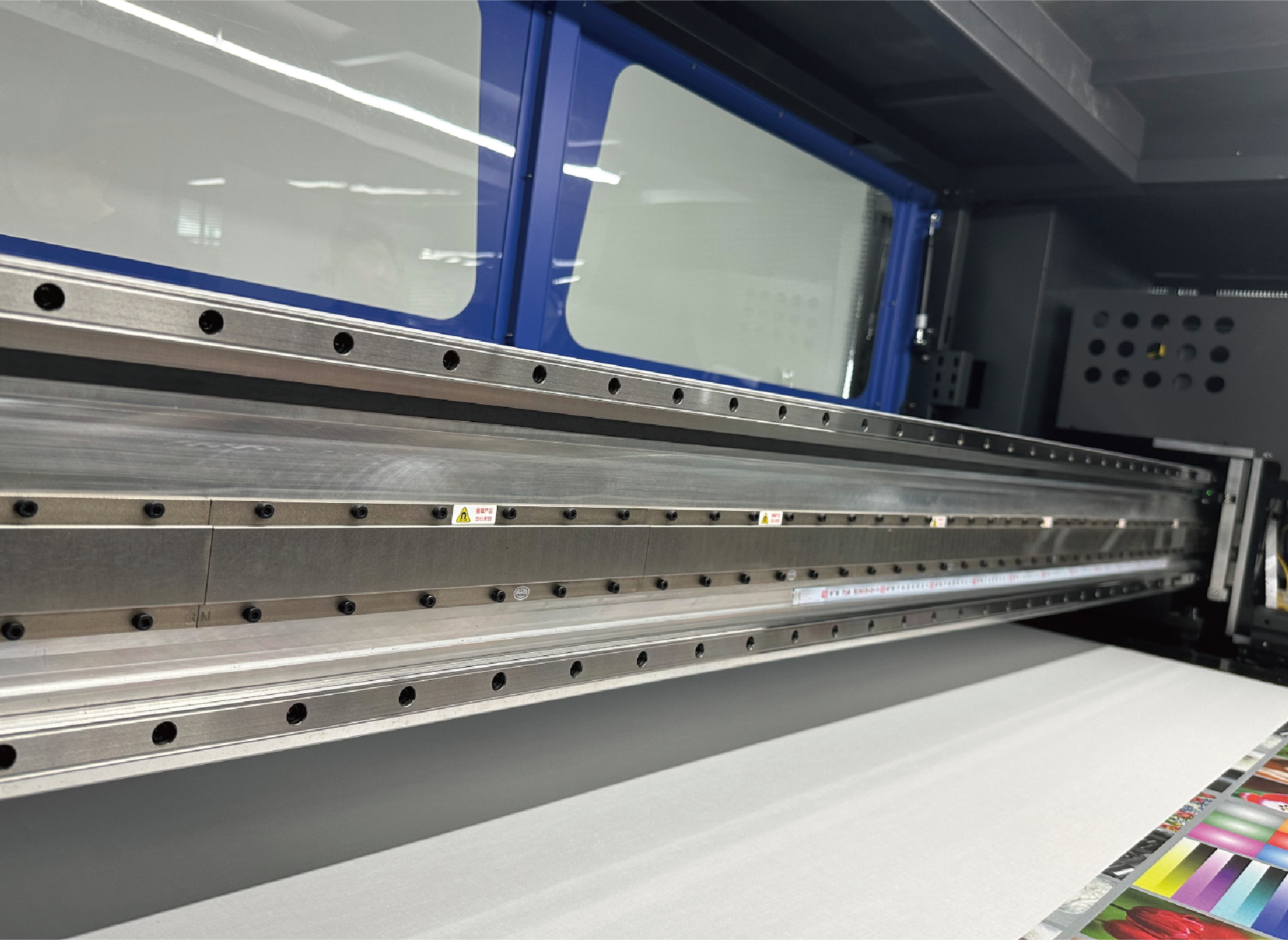

High-density, high-precision fabric mediabelt systems & gluing platform, better fitthe fabric, accurate fabric stepping

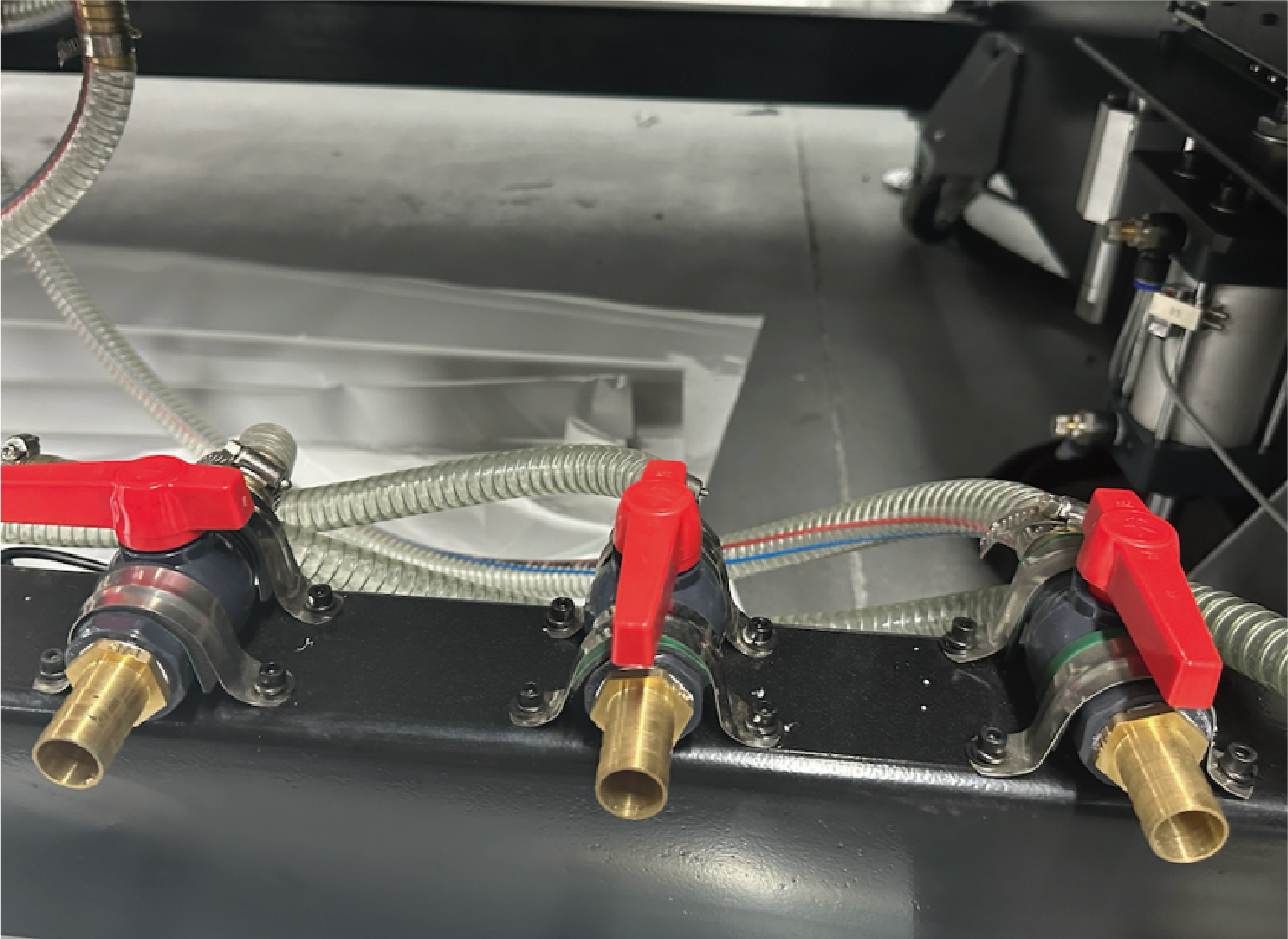

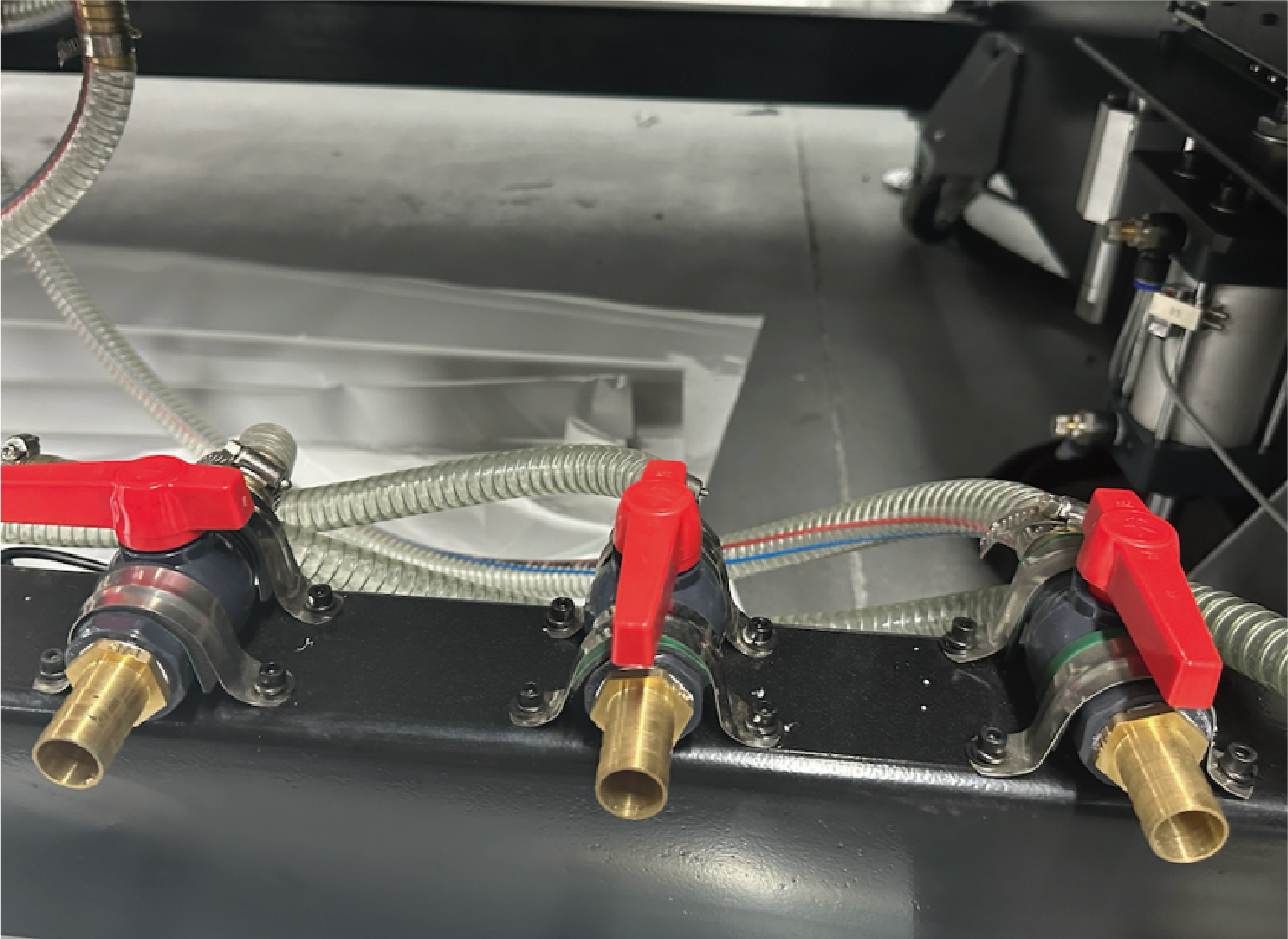

Ink negative pressure system,better ink fluency, ensuring stableoutput for high-speed production

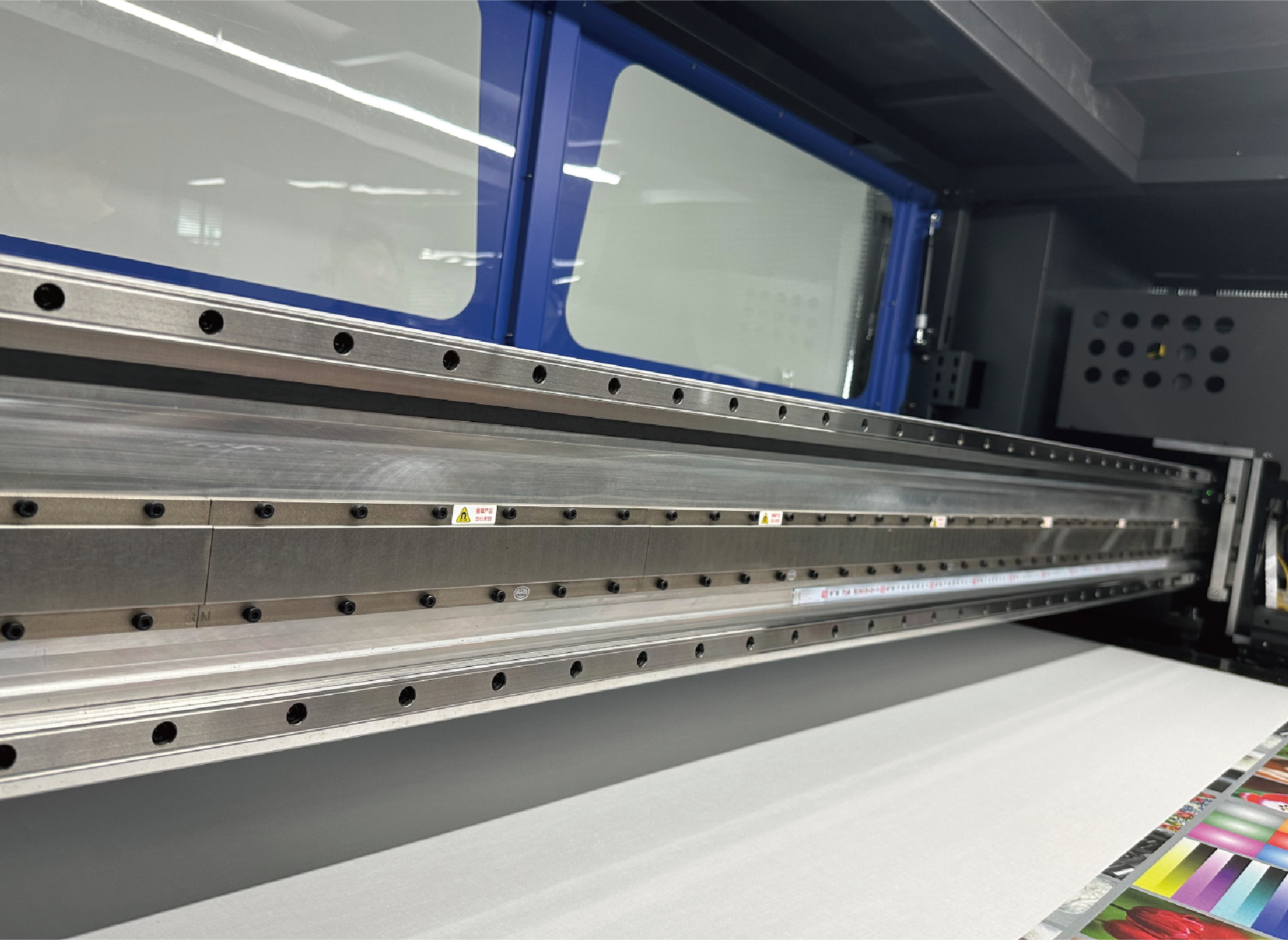

Double THK guide + linear motor,more stable printing, better speedimprovement, higher precision output

The special feeding system for fabricscan adapt to cotton fabrics of differentthicknesses

The guide belt is equipped withwater-based function to ensure that thefabric is clean and also can adapt tomore ink application solutions

Equipped with a belt-guided spongebrush, it can be cleaned while printingto ensure that the fabric is clean andtidy during the printing process

|

Cost-effective industrial rack, industrial production capacity

High eficiency, low cost, high precision to create excellent printing quality, ultra-high cost to meet the fast one-

click printing and high-end design customization needs.

|

HD printing, imaging details are clear.

High speed and stability, one key design customization Using linear motor + magnetic grid + magnetic levitation,greatly improve the stability of printing to ensure high-quality continuous output, through special combination andcontrol svstem to maximize the productivity of the nozzle. so that vou can face mass orders can also be handy.

|

Intelligent design, easy to understand operation

Automatic print head cleaning system, moisturizing system, automatic belt cleaning and maintenance system design.simple operation and maintenance, protect the eficiency of the machine, make it possible for one person tooperate the machine.

|

Detail creation, perfect printing experience

The operation is simple. the coth surface fattening effect is good. modular desian, the maintenance of each componentis convenient and brief, the ink replacement is quick and convenient, the degree of automation is high, the print head iscleaned by one key and moisturized by one key.

High-density, high-precision fabric mediabelt systems & gluing platform, better fitthe fabric, accurate fabric stepping

Ink negative pressure system,better ink fluency, ensuring stableoutput for high-speed production

Double THK guide + linear motor,more stable printing, better speedimprovement, higher precision output

The special feeding system for fabricscan adapt to cotton fabrics of differentthicknesses

The guide belt is equipped withwater-based function to ensure that thefabric is clean and also can adapt tomore ink application solutions

Equipped with a belt-guided spongebrush, it can be cleaned while printingto ensure that the fabric is clean andtidy during the printing process

GREEN FUTURE . GREEN GREEN